Altilium announced a partnership with Lunaz to develop an innovative and low carbon logistical solution for the safe transportation and discharging of end-of-life EV batteries.

The pioneering project, which has received funding from the Automotive Transformation Fund (ATF), is the latest addition to Altilium’s comprehensive ecosystem of technological solutions, developed to ensure the responsible management of EV batteries, from end-of-life collection to direct re-use of recovered materials in the production of new batteries.

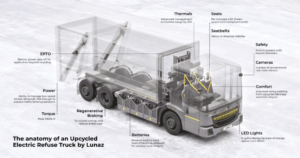

Through this collaboration, Lunaz’ team of engineers will utilise its electrification expertise and proprietary technology to develop a prototype upcycled electric Heavy Goods Vehicle (HGV), specifically designed to transport end-of-life EV batteries, and capable of harvesting and running on electrical energy remaining in the batteries. This will enable their efficient, sustainable transport to Altilium’s planned recycling facilities, with the lowest environmental impact, while also discharging them prior to recycling.

Through this collaboration, Lunaz’ team of engineers will utilise its electrification expertise and proprietary technology to develop a prototype upcycled electric Heavy Goods Vehicle (HGV), specifically designed to transport end-of-life EV batteries, and capable of harvesting and running on electrical energy remaining in the batteries. This will enable their efficient, sustainable transport to Altilium’s planned recycling facilities, with the lowest environmental impact, while also discharging them prior to recycling.

Altilium plans to open the UK’s largest EV battery recycling plant in Teesside in 2026. The facility will have the capacity to recycle batteries from 150,000 EVs a year, producing 30,000 MT of Cathode Active Materials (CAM) for return and reuse in the EV battery supply chain. By expanding its activities into spent battery collection and management, Altilium will be uniquely positioned to tackle the high levels of end-of-life battery waste expected in the UK (around 1.4 million batteries per year by 2040), as part of its full battery circularity customer offering.

By upcycling existing vehicles, Lunaz allows fleet operators and governments to transition their industrial vehicle fleets to clean-air powertrains while reversing the ecologically damaging cycle of replacing-with-new. Every upcycled electric vehicle (UEV) produced by Lunaz saves up to 82% of the embedded carbon within that vehicle. Lunaz’ technology has already been proven in prototype vehicles, with the first upcycled fleet of vehicles set to roll out later this year, through a partnership with waste management company Biffa.

By upcycling existing vehicles, Lunaz allows fleet operators and governments to transition their industrial vehicle fleets to clean-air powertrains while reversing the ecologically damaging cycle of replacing-with-new. Every upcycled electric vehicle (UEV) produced by Lunaz saves up to 82% of the embedded carbon within that vehicle. Lunaz’ technology has already been proven in prototype vehicles, with the first upcycled fleet of vehicles set to roll out later this year, through a partnership with waste management company Biffa.

Work will be performed at Lunaz’ upcycling campus in Silverstone, which has capacity to upcycle more than 1,110 industrial vehicles to zero emissions powertrains every year.

Transporting old EV batteries is challenging and expensive, given their weight and health and safety risks. On average, transportation represents 41% of the total cost of recycling and contributes 3.5% of life cycle GHG emissions for a recycled battery. Through this project, Altilium hopes to reduce the carbon footprint of battery recycling by up to 5%.

Source: Altilium

Be the first to comment