HyProMag, the pioneering rare earth recycling company is to be acquired by Maginito Ltd, in a deal that aims to catalyse the further scale-up and recycling.

HyProMag is formed by researchers from the University of Birmingham’s School of Metallurgy and Materials at the University of Birmingham and forming the basis for the UK’s first full scale remanufacturing facility for rare earth magnets at Birmingham’s Tyseley Energy Park being developed later this year.

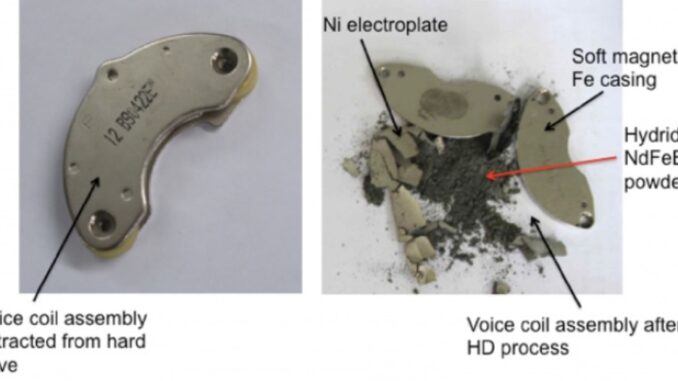

HyProMag’s core technology is the based upon the patented process – Hydrogen Processing of Magnet Scrap (HPMS), which was originally developed within the University’s Magnetic Materials Group (MMG) to extract rare earth magnets from scrap and redundant equipment and subsequently licensed to HyProMag.

Rare earth magnets play a key role in clean energy technologies including electric vehicles and wind turbine generators. They are also a key component in electronic devices including mobile phones, hard disk drives and loudspeakers.

Maginito focuses on developing green technology opportunities in the rare earths supply chain (90% owned by Mkango and 10% by CoTec). Mkango has partnered with HyProMag since its inception in 2018. A new US subsidiary, jointly owned by Maginito and CoTec, is expected to be formed to develop rare earth recycling opportunities in the United States.

The companies have a shared vision to create a large-scale, international business focused on downstream rare earth technologies, with major competitive advantages in the rare earth recycling sector, including the patented energy-efficient technology for recycling magnet scrap.

The development of domestic sources of recycled rare earths in the UK, Germany, United States and other territories is a significant opportunity to fast-track the development of sustainable and competitive recycled rare earth magnet production.

HPMS is used to reduce permanent magnets containing neodymium (Nd) iron (Fe) and boron (B) to a demagnetised powder. The technology was developed by the late Professor Emeritus Rex Harris, former Head of the University’s Magnetic Materials Group, with Professor Allan Walton, current Head of the Magnetic Materials Group (MMG). Hypromag was founded in 2018 by Prof Walton and Harris alongside two Honorary Fellows, Dr John Speight and Mr David Kennedy, to develop a full recycling supply chain for rare earth magnets based upon neodymium iron boron (NdFeB).

The MMG has been active in the field of rare earth alloys and processing of permanent magnets using hydrogen for over 40 years, and the four founding directors are all world-leading experts in the field of rare earth magnetic materials, alloys and hydrogen technology, with significant industry experience.

The MMG has been active in the field of rare earth alloys and processing of permanent magnets using hydrogen for over 40 years, and the four founding directors are all world-leading experts in the field of rare earth magnetic materials, alloys and hydrogen technology, with significant industry experience.

A pilot plant for HPMS recycling opened at the University of Birmingham last year, and work is now underway to build a large scale ‘short loop’ recycling facility at Tyseley and other locations using the patented HPMS process to provide a sustainable solution for the supply of NdFeB magnets and alloys for a wide range of markets including automotive and electronics. First production is expected in the UK in 2023 and in Germany in 2024.

Short loop magnet recycling is expected to have significant environmental benefit, requiring an estimated 88% less energy versus primary mining to in order to produce a sintered magnet.

The Tyseley plant is being developed with the University of Birmingham and is expected to have a minimum production capacity of 100 tonnes a year. This £4.3 million project is being funded by Driving the Electric Revolution, an Industrial Strategy Challenge Fund delivered by UK Research and Innovation.

The founding Directors and management of HyProMag will continue to provide support and work closely with Mkango and Maginito to further scale-up and roll-out the HPMS technology.

Source: HyProMag

Be the first to comment