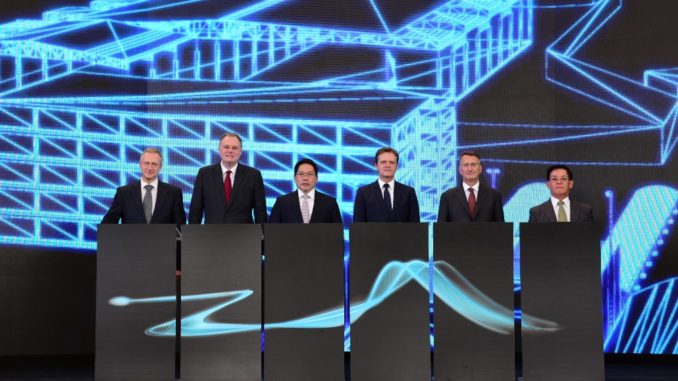

Mercedes Benz cars and local partner Thonburi Automotive Assembly Plant (TAAP) will further deepen their cooperation and will jointly invest a total of more than 100 Million Euros in their manufacturing footprint in Bangkok, addressing growing demand for electric mobility in the region, building an extension of the existing car plant and into a new battery assembly built on the site ensuring availability of cutting-edge technology for electrified and “EQ Power” Plug-In Hybrid vehicles produced in Thailand.

The electric initiative in the flexible and efficient global production network of Mercedes-Benz Cars is progressing well and with ultimate speed. As part of our strategy, we are now preparing for the future of electromobility in Thailand together with our partner TAAP. With our highly standardized and scalable battery production concept we are able to start operations in any region at short notice and at the right size. The battery production in Thailand will enhance our global battery production network to six factories on the three continents – states Markus Schäfer, Member of the Divisional Board of Management Mercedes-Benz Cars, Production and Supply Chain.

Thanks to a standardized production and plant concept, the battery production concept of Mercedes-Benz Cars can be scaled in such a way that various value-added stages as well as production concepts can be implemented flexibly and in line with the markets worldwide.

Dr. Uttama Savanayana, Minister of Industry in Thailand:

Mercedes-Benz is one of the world’s biggest carmakers and a leading manufacturer in Thailand with its world-class standards of products and services. The company’s investment in Thailand generates a currency inflow and contributes to the economic, technological and social developments of our country. Mercedes-Benz has applied for promotional privileges for its new investment in Plug-In Hybrid electric vehicle (PHEV) production, which coincides with Thailand’s automotive industry development towards the future of electric vehicles and supply chain development. This new move reflects the confidence that the German carmaker has in Thailand as its key production base in this region. The investment will also bring to Thai people an opportunity to heighten their competence with better know-how and higher technologies than conventional auto-part production, which will contribute significantly to the progress of Thailand’s automotive industry and drive the nation’s development strategy towards tangible results.

By 2022, Daimler will electrify the entire portfolio of Mercedes-Benz, offering customers at least one electrified alternative in all segments from compact cars to large SUVs. The company is planning to offer more than 50 electrified vehicle variants. Mercedes-Benz will be continuously supporting the development of Plug-In Hybrids and the introduction of 48-volt-systems.

The first EQ series model- the EQC – will go into production in 2019 in Bremen, Germany.

The product and technology brand EQ is an integral part of CASE, which stands for the intelligent combination of the strategic pillars of connectivity (Connected), autonomous driving (Autonomous), flexible use (Shared & Services) and electric drive systems (Electric).

Sixth Mercedes-Benz factory to produce batteries

The battery production in Bangkok will be part of the global battery production network of Mercedes-Benz Cars for local demand and export.

In total, Daimler will invest more than one billion Euros in the battery production network, which will also include production facilities in Germany, the U.S. and China.

As in vehicle production, the battery production network will react flexibly and efficiently to market demand.

This strategy ensures the ongoing availability of modern battery technology through local production hubs and puts Mercedes-Benz in a highly competitive position for its electric initiative.

Local production of batteries in Thailand is planned to start by 2019.

Be the first to comment