Williams Advanced Engineering (WAE) unveiled its latest electric vehicle innovation: an ultra-high performance electric vehicle platform.

The platform has been designed to accelerate the ambitions of hypercar manufacturers, from start-ups to OEMs.

With its first public showing at the Low Carbon Vehicle Show, the new EVR concept enables brands to launch unique high-performance electric vehicles based on a state-of-the-art yet cost-effective platform; combining WAE’s extensive vehicle and powertrain engineering experience in one innovative package.

Just one of several EV-focused innovations on display at the event at the Millbrook Proving Ground, WAE is also unveiling its new Scalable Battery Module (SBM) system and the prototype Triumph TE-1 electric motorbike together with the e-powertrain, underlining its position as a leader in high performance electrification.

EVR – the advanced platform for tomorrow’s electric hypercars

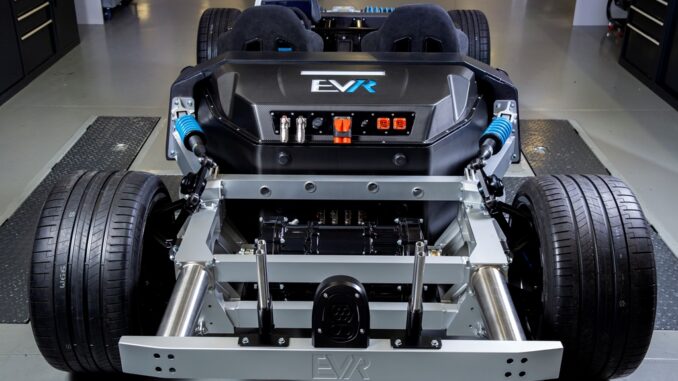

The latest iteration of WAE EV platforms, EVR is focused on the growing electric hypercar sector, with a lightweight composite structure that mounts the high-performance battery system in the middle of the vehicle, optimising centre of gravity.

EVR can support a range of electric hypercar configurations, from track-only vehicles where power-to-weight is maximised to roadgoing models, both open-roof Targa and fixed-roof GT architectures. This is made possible by the architecture’s central tub which has been designed from day one to allow for such flexibility, including open roof design, whilst still featuring the very latest performance technology such as active aerodynamics.

With a state-of-art 85kWh battery and peak power of 1650kW, EVR enables sub-2.0secs 0-100km/h acceleration and a top speed more than 400kmh (248mph) with a vehicle mass less than 1800kg, along with fast-charging capability of sub-20mins and a range in excess of 450km (279 miles). All-wheel drive and rear-wheel drive layouts are supported through multiple e-motor configurations.

EVR’s inherent flexibility and modularity means WAE’s offering to customers is unique. For start-ups, EVR provides a complete turnkey solution, with WAE delivering the entire vehicle, with exterior design support supplied by the customer or a WAE partner.

For OEMs, EVR accelerates route to market, with the entire engineering and assembly of the rolling chassis completed by WAE. Capable of being adapted for both the OEM’s design and styling requirements, EVR reduces time from development to market launch.

Equally, for OEMs and Tier 1s, EVR provides the opportunity to integrate new products to push the boundaries of electric powertrain technology, with the rolling chassis capable of being continuously developed with WAE’s newest motor and battery technologies.

Engineered for maximum flexibility for customer requirements, both in terms of interior and exterior design, EVR results in a reduced time to market with class-leading performance, with WAE targeting delivery of a first EVR-based prototype within 12 months from project kick-off to delivery of a first production vehicle in 24 months.

EVR is also ready for a hydrogen future with an EVR-H fuel cell variant also being developed to deliver the equivalent performance of a pure BEV platform but powered by green H2.

Scalable Battery Module – a paradigm shift in rapid and flexible battery development

Another debut at CENEX LCV is WAE’s Scalable Battery Module (SBM). Utilising WAE’s proprietary ‘Sense Chain’ architecture, the SBM system eliminates the replication of electronics, while enabling independent scaling of voltage and capacity and the realisation of bespoke battery concepts in record time.

Another debut at CENEX LCV is WAE’s Scalable Battery Module (SBM). Utilising WAE’s proprietary ‘Sense Chain’ architecture, the SBM system eliminates the replication of electronics, while enabling independent scaling of voltage and capacity and the realisation of bespoke battery concepts in record time.

Revolutionising rapid and flexible battery development, WAE’s modular toolkit enables automotive customers to create custom pack and sub-pack systems faster than ever, supporting low-medium volume electric vehicle developers across a range of industries. Each module is 1.08kWh with a voltage of 50V Max, 43V Nominal with an energy density of >240Wh/kg.

Triumph TE-1 – advancing electric motorbikes

Also on display at CENEX LCV will be the Triumph TE-1 prototype bike together with the electric powertrain, developed by WAE. A unique collaboration between Triumph Motorcycles, WAE, Integral Powertrain Ltd, and WMG, University of Warwick, funded by the Office for Zero Emission Vehicles through Innovate UK, the TE-1 project was set up to create ground-breaking developments in specialist electric motorcycle engineering and innovative integrated technology design.

WAE’s battery technology delivers ‘real world’ e-motorbike solutions with a range of 161 km (99miles), 130 kW of peak power, a weight of just 220kg and a 0-80% charging time of only 20mins.

In line with this planned expansion, WAE will also be showcasing the opportunities for anyone wishing to join our rapidly expanding global team and committed to delivering a zero emissions future.

Source: Williams Advanced Engineering

Be the first to comment